Week 8: Zeolite Completion and Powder Delays

Hey everyone, welcome back to my blog!

Last Thursday, I ran the powdered silica gel experiment again, but there were still problems related to powder loss. I struggled to remove the desiccant chamber after adsorption because there was friction between the tape around the funnel/chamber and the side of the system. So, a lot of powder got stuck to the sides and some powder fell through the system onto the fan. I tried to salvage as much powder as possible by scooping it back into the desiccant chamber, but the final weight ended up being 9.7 grams, less than the original 10 grams, so it was a failed experiment.

My professor suggested that there are gaps around the sides of the chamber when it is placed inside the system, causing the powder to fall through. He suggested that I put Teflon tape on the top edges around the chamber, so I will try this new method when I rerun the silica gel experiment and do the blue silica gel experiment later this week.

On Friday, I competed in the AZ Science Fair and it was very fun! The judges were all really nice and genuinely interested in my project, so I was able to teach them about Atmospheric Water Capture while also practicing my presentational skills for the senior project presentation. One of my judges who had background knowledge in desiccants and AWC was even able to provide me with tips on how to proceed with my project/future work.

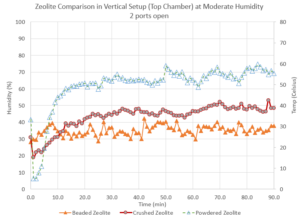

Today, I proceeded with my zeolite plan and tested beaded zeolite in the vertical setup. Because of the beaded form, the zeolite was not able to fluidize (move around and act like a gas). I expected that due to this lack of fluidiization, it would be hard for the humidity in the bottom chamber to fully pass through the desiccant and into the top chamber. This hypothesis was right, as the humidity in the top chamber stayed almost 20% lower than in the bottom chamber. But, after running adsorption for 90 minutes as I did for the powdered and crushed zeolite experiments, the adsorption capacity of the beaded was actually greater. I assume this is due to the immense powder loss in the powder and crushed experiments.

I graphed the three adsorption curves on a single graph in Excel to compare the different rates. On Thursday, I am going to discuss more with the grad student about how to find the kinetic curves from the data and how to determine which order they are.

Besides more experiments in the lab, I have been simultaneously revising my poster based on new data as well as working on my final paper. Next week will be a buffer week and time to complete any last powder experiments, but I am planning on finishing both powdered silica gels on Thursday and doing powdered activated alumina on Friday, assuming all goes well with the setup.

That’s all for this week, thanks for reading!