Week 4: More Troubleshooting and Modifications

Hi everyone, welcome back.

This week consisted of more calibrating tests since each day a new problem with the dehumidifier setup seemed to appear. On Friday, my professor and I first moved the bottom chamber’s temperature sensor farther down to ensure it wasn’t too close to the heater, which ended up fixing the high-temperature issue. Then, I ran 5 scenarios: one with just the fan; one with the humidifier and fan; one with the humidifier, fan, and heater; one with the humidifier, fan, and zeolite powder; and one with the heater, fan, and zeolite powder. From my Excel graphs, it was clear that there was a problem with the bottom chamber’s humidity. There was too much air coming in, so I experimented with plugging/blocking one of the two ports in the bottom chamber that might have been causing this airflow. Also, we added a water trap on the humidifier tube to ensure that the moisture and water were not mixing and skewing the humidity sensor readings. Pictured below are the bottom chamber’s temperature sensor’s new location, the plug in one of the ports, and the water trap.

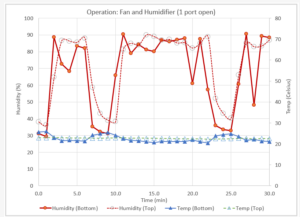

Below is the graph of the trial I ran with the fan and humidifier on, with only one port open. There are sudden drops in the humidity because I kept emptying the trap when there was water accumulation, but if I had kept it closed the entire time, the humidities of both chambers would have been constant/followed the proper trends.

On Monday, another issue arose. When I turned the fan on more than 0.1 amperes, there was a piercing ringing/screeching noise. My professor quickly deconstructed the humidifier, realigned and greased the fan, and cut part of the port that was interfering with the blades, which luckily fixed the squeaking and allowed the fan to reach over 1 ampere.

On Tuesday, while running trials with just the heater and fan on, there continued to be problems with the humidities of both chambers. They kept fluctuating severely, so we first moved the bottom chamber’s humidity sensor down next to the temperature sensor. Then, since we believed the fan may have not been blowing in the right direction, we replaced it with an air blower. The air blower actually made the problem worse, since it began blowing hot air and drying the system, causing the humidity of the bottom chamber to stay below 20% when it should have been around 90%.

I then switched back to the fan and the humidity seemed to be good, but I was not able to run a full trial. So today I am going to do another calibrating test (hopefully my last one) and if all goes well, I will be able to start testing my desiccants today or tomorrow.

This has been a great experience so far to go through the process of making sure all the tools work, and identifying and solving these minor issues with the setup has definitely helped me think like an engineer! Stay tuned as I’m hoping to have more updates next week!