Week 2: Advancing KnoxFog™ – Prototype Development and Application Optimization

Welcome back to my research blog!

This past week has been full of exciting developments as I continue understanding the KnoxFog™ coating for its application in medical devices, particularly in endoscopic surgery. While I have been working on datat analysis, I want to catch you all up on:

- Enhancing the durability of KnoxFog™ for prolonged surgical procedures

- Developing a prototype silicone compartment for controlled application

- Testing sterilization methods to ensure clinical compatibility

Improving KnoxFog™ Longevity and Stability

In my initial testing, KnoxFog™ demonstrated excellent anti-fogging performance, but prolonged exposure to surgical conditions showed some degradation over time. This week, I worked on modifying the formulation to improve its longevity while maintaining its hyper-hydrophilic properties.

Two key ideas of this new solution is:

- It is Semi-Solid – this means that the application is easy to apply since it is still viscous and it takes less time to dry (since it is close to a solid). Other solutions that are purely liquid take too long to dry – potentially increasing surgery time,cost, and scarring – and other solutions that are solid are hard toapply to the lens

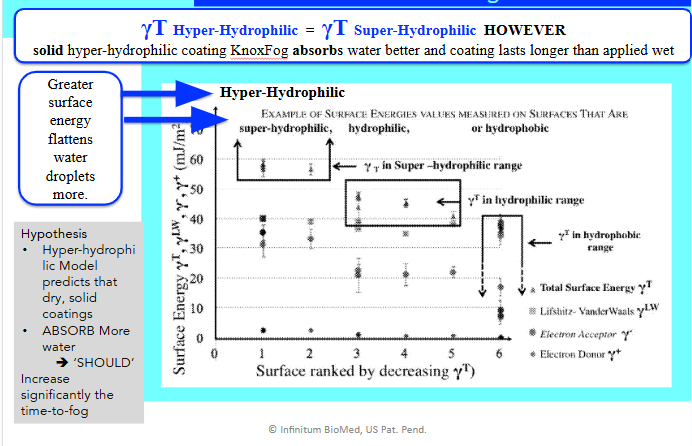

- It is Hyper-hydrophilic – this means the the solution matches its surface energy with that of water in order to completely flatten the droplet and prevent distortion (shown below in the diagram); increasing surface energy and hydroaffinity will flatten the drople more. Since like attracts like and the solution has the same surface energy as water, the water is compltely flattened on the lens, preventing distortion and increased visibility.

In last weeks blog post, I also included a diagram that shows a 2D representation of hydrophobic vs. hydrophilic vs super and hyper-hydrophilic surfaces. Refer back to last week for a detailed representation.

Early results:

✔️ Improved retention – The formulation adhered better to surgical optics, reducing the frequency of reapplications.

✔️ Sustained clarity – Fog-free performance extended beyond 60 minutes in simulated conditions, a major improvement over previous trials.

✔️ Increased chemical resilience – The updated formulation withstood exposure to standard surgical disinfectants without breaking down.

Developing the Silicone Casing Prototype for Precise Application

A key area of focus has been developing a silicone casing that houses and dispenses KnoxFog™. This will ensure controlled and sterile application, reducing contamination risks and making the application process more efficient.

As lead engineer for R&D of the original prototype, the key parts of the prototype development process include:

1. We first create 3 sets of 5 identical mock-up prototypes

- Each set test a specific, FDA-approbed adhesive OR silicone tape to test adhesion of various polymers

2. Design comprises of two BOXES serving as two compartments

- to apply FogKnox™solution

- to DRY the applied FogKnox™ film in five seconds

3. FDA-Grade Polymer Materials USP Class IV Polypropylene outer boxes FDA-Grade Silicone dabber to apply FogKnox™

Three Adhesive Tested:

- Weldbond Glue

- Silicone Glue

- FDA-Grade SIlicone Tape

Since our solution is now semi-solid, we no longer need a drying comparment → this allows for a single compartment silcone casing rather than double.

Whats Coming Up?

Next week, I will focus on scaling up production for more extensive testing, including:

- Comparative trials with current anti-fogging methods (e.g., heated lenses, alcohol-based coatings, no coating) under varying conditions.

- The actual experimentaion procedure and design

- Collaboration with surgeons at Banner Health to gain insights into real-world needs.

In future weeks, we will talk about the results and the comparison of the antifog solution to an uncoated lens, sterility testing, and animal testing.

I’m excited to see how these developments will shape the future of fog-free medical optics. Stay tuned for next week’s updates, where I’ll dive deeper into real-world testing and clinical validation.

As always, feel free to share your thoughts or questions – I’d love to hear your feedback!

Also, I know the difference between the FogKnox vs KnoxFog is very confusing, please let me know if I should make an additional blog post dedicated to clarifying the differences between the two?

Finally, thank you so much to Professor Herbots for providing me with the resources to conduct this research, the mentoring on the science behind this project, and the previous years of experience/foundation to build my project off of. Also, thank you Mr. Schaffer for mentoring me from school on my expectaions and pacing for my project alongside other great expertise.

Best regards and happy readings,

Shreyash

Comments:

All viewpoints are welcome but profane, threatening, disrespectful, or harassing comments will not be tolerated and are subject to moderation up to, and including, full deletion.