Testing Complete

Hey everyone! I have finished testing both groups of composites. The process for doing the tensile test is surprisingly simple.

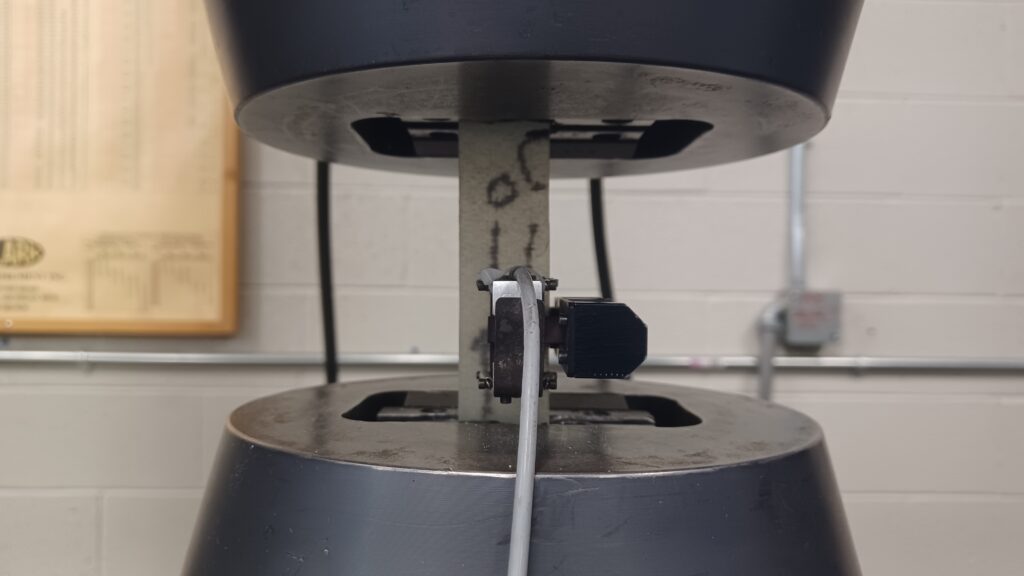

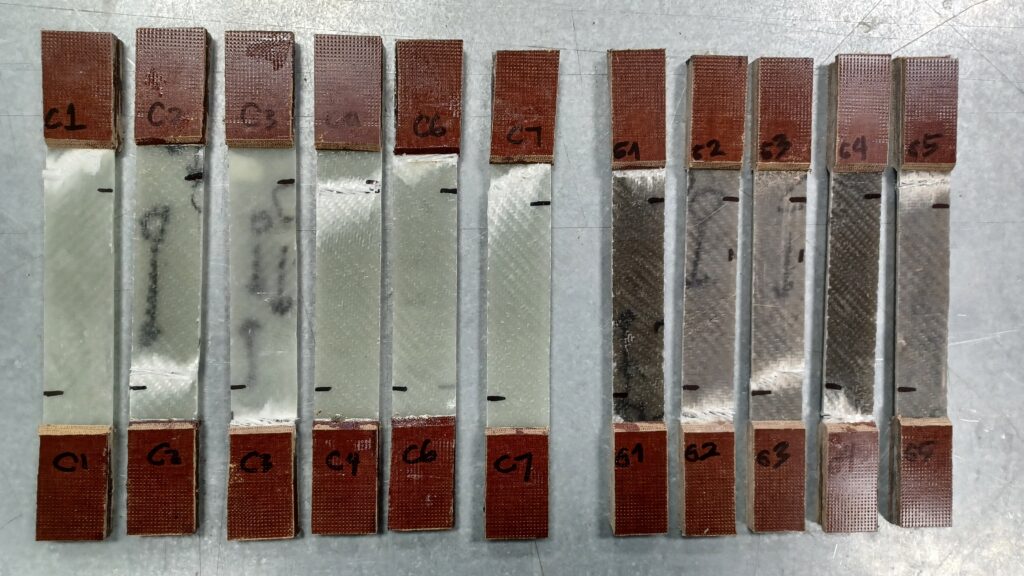

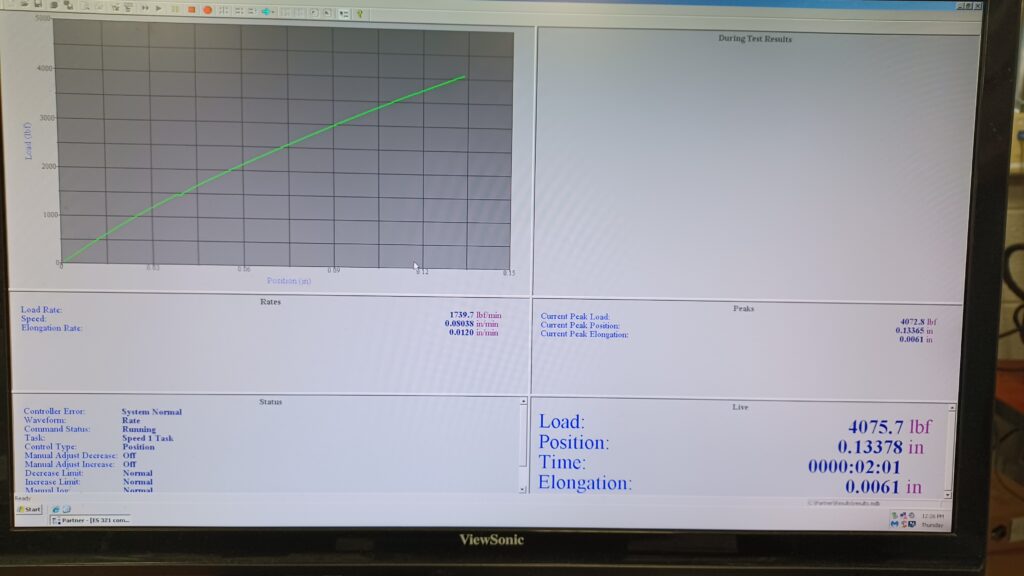

In the material testing lab, I first measured the length, width, and thickness of each specimen with a caliper. Then, with the help of another student, we placed each specimen into the grip clamps on the tester. There are two levers on a control panel on the side that control the clamps. Once the specimen was inside the grips, we added the extensometer. After that, all we had to do was zero the measurements on the computer and run the test. The machine will start adding load slowly, and once the specimen fails, the program outputs a CSV text file with the raw data points from the test.

After each test, I make a note of the failure code of each specimen according to ASTM D3039 (the standard for fiber composite tensile testing). These three letter codes show the failure type, area, and location. For example, the failure code for C2 is LGM. “L” means it failed laterally across the specimen, “G” means it failed at the gauge, or the middle area of the specimen, and “M” means it failed in the middle. There were lots of different areas and types of failures throughout testing, but the ultimate load when the specimens broke stayed consistent, so I know that each test specimen was relatively similar.

With this data, I will now need to do some calculations. For each specimen, I will need to find the stress on the part, which is the force per unit area of the material. The highest stress the material endured before breaking is the ultimate tensile strength. I will also calculate the elastic modulus of each specimen, which relates the stress with how much the material stretches. Once I have these numbers, I can finally see if the graphene oxide had any beneficial effects.

Comments:

All viewpoints are welcome but profane, threatening, disrespectful, or harassing comments will not be tolerated and are subject to moderation up to, and including, full deletion.