A Penguin, a Motherboard, and a Sapling Walk into a…

Tanay N -

As stated in my last blog post, this week will be divided into two parts: Aether and lab work at ASU.

Aether

As said before, I want to run it with an incense stick to sort of mimic putting these units in “steam stacks” or temporarily high CO2 density areas. Although CO2 does diffuse evenly throughout the atmosphere over time, places with recent fires/heavy pollution have temporarily very high levels of CO2, so I was thinking that this test with the incense stick could demonstrate potential scalability and usefulness in different aspects such as providing relief for households from wildfire smoke, etc.

Saturation Hypothesis

I set the cycle time to two hours with the incense stick burning (outside the reaction chamber but next to the air pump so that the air which was pumped into the reaction chamber would contain a high amount of CO2), and Aether actually ended up capturing a good amount of CO2. (I want to save the exact amount for the final presentation, as it’s actually really surprising!) Furthermore, this result proves that our sorbent (Calcium hydroxide powder) does in fact get saturated by CO2; excess carbon dioxide just flows right through the system. This means that the inner layer of the Ca(OH)2 isn’t reacting. The image below can depict this theory a bit better.

I want to run this cycle again but without the burning incense stick. This would be to confirm my theory of saturation. If the same amount of CO2 is captured, then that means the sorbent does in fact get saturated (the capture yield isn’t affected by the CO2 percentage in the air). If so, this would also mean that Direct Air Capture units can be effective anywhere they are placed in the world, no matter if the location has a low CO2 content. For example, running an advanced version of Aether in the Arctic could technically lower CO2 levels in Delhi, India.

On the other hand, however, if the CO2 captured is lower without the incense stick compared to with the incense stick, then this means that saturation happens at a later time. For our purposes, this shows that an increased amount of CO2 in the air results in an increase in capture rates, and DAC units are more effective if placed in highly polluted areas such as Delhi, so we should focus our industrial DAC projects in that location.

Either way, DAC units still capture CO2 which is a win in my book! 🙂

At the Center for Negative Carbon Emissions

The title of today’s blog post is “A Penguin, a Motherboard, and a Sapling Walk Into A…” You can probably recognize that this title takes on the format of a classic joke. However, you may be inclined to know that the three words in the title represent my week at ASU’s Center for Negative Carbon Emissions (CNCE).

Modelling sorbents, CO2 sensors, and computational chemistry at the CNCE all require use of the operating system “Linux,” whose mascot is a penguin. You can see where I’m going with this. All jokes aside, this past week involved a lot of learning how to navigate changing directories, lists, and converting CO2 sensor readings into, well, something we can actually read.

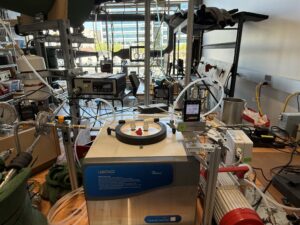

“Motherboard” is the name of CNCE’s primary Moisture-Swing (MS) technology. The image below is of this machine. I’m enormously grateful that my mentors Dr. Matthew Green and Mr. Matthew Ryan have allowed me to learn how to operate the CNCE’s tech on my own, possibly being able to conduct my own experiments. The image below is of Motherboard.

“Sapling” is the name of CNCE’s smaller version of their “Mechanical Tree” which operates under Thermal-Swing (TS) technology. An explanation of both MS and TS can be found in my first blog post. The below images are of Sapling.

As you can tell, both machines looked quite daunting to me at first, and so it took many hours in the lab tinkering with valves and following tubing to understand exactly how the Sapling and Motherboard operate.

Challenges!

One major challenge was leaks in the system. As you can see, there are countless joints in the steel pipes, so this can lead to leaks over time. Once I pulled vacuum, our flow meter (which provides us with the air flow in the pipes) was actually not dropping. This means that as we were pulling air out of the system, air was going into the pipes through the leaks (small holes) in the joints. Over the next few days, fortunately, we were able to close off all the leaks and saw our vacuum drop pretty low. Other hiccups involved not closing the correct valves. The below pictures are of the vacuum (the silver box and the red outlined box) and me while trying to fix the leaks.

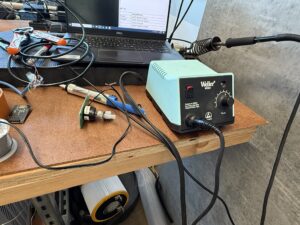

Another major hurdle involved the breaking of the CO2 sensor itself. The soldering on the wires just came clean off, so we had to resolder it. I had to learn soldering for this task as well. The image below is of the soldering setup.

Furthermore, we had to make sure we were soldering the correct wires in the correct places or the CO2 sensor wouldn’t work. As a result, I had to learn some basic electronic mapping to make sure the RXD (receiver) and the TXD (transmitter) were in the correct spots. This took quite a while, as the wiring that connects to the automatic data logging for the laptop looks like this:

Finally, however, we had finished soldering and the CO2 sensor worked. By this time, I was finally able to do a complete run of Sapling without many problems. Currently, I’m doing some data analysis on the numbers that the sensor and the flow meters read to make sure there are zero discrepancies.

I’m also in the process of making my poster and final presentation. In my next blog post, I’ll go into exactly how the Sapling works and hopefully I can provide you all with some data on industrial-level sorbents which you can see in the picture below (I’ll be putting these into the large green chamber of Sapling).

As always, thank you to Dr. Matthew Green and Matthew Ryan at CNCE for allowing me to work with Sapling and guiding me through the process. And thank you to Ms. Holtzman for allowing me to test different scenarios like the incense stick. I’m grateful to all of you for reading and for commenting on my posts! I’ll see you next week 🙂

Comments:

All viewpoints are welcome but profane, threatening, disrespectful, or harassing comments will not be tolerated and are subject to moderation up to, and including, full deletion.