New Batches with Graphene Oxide

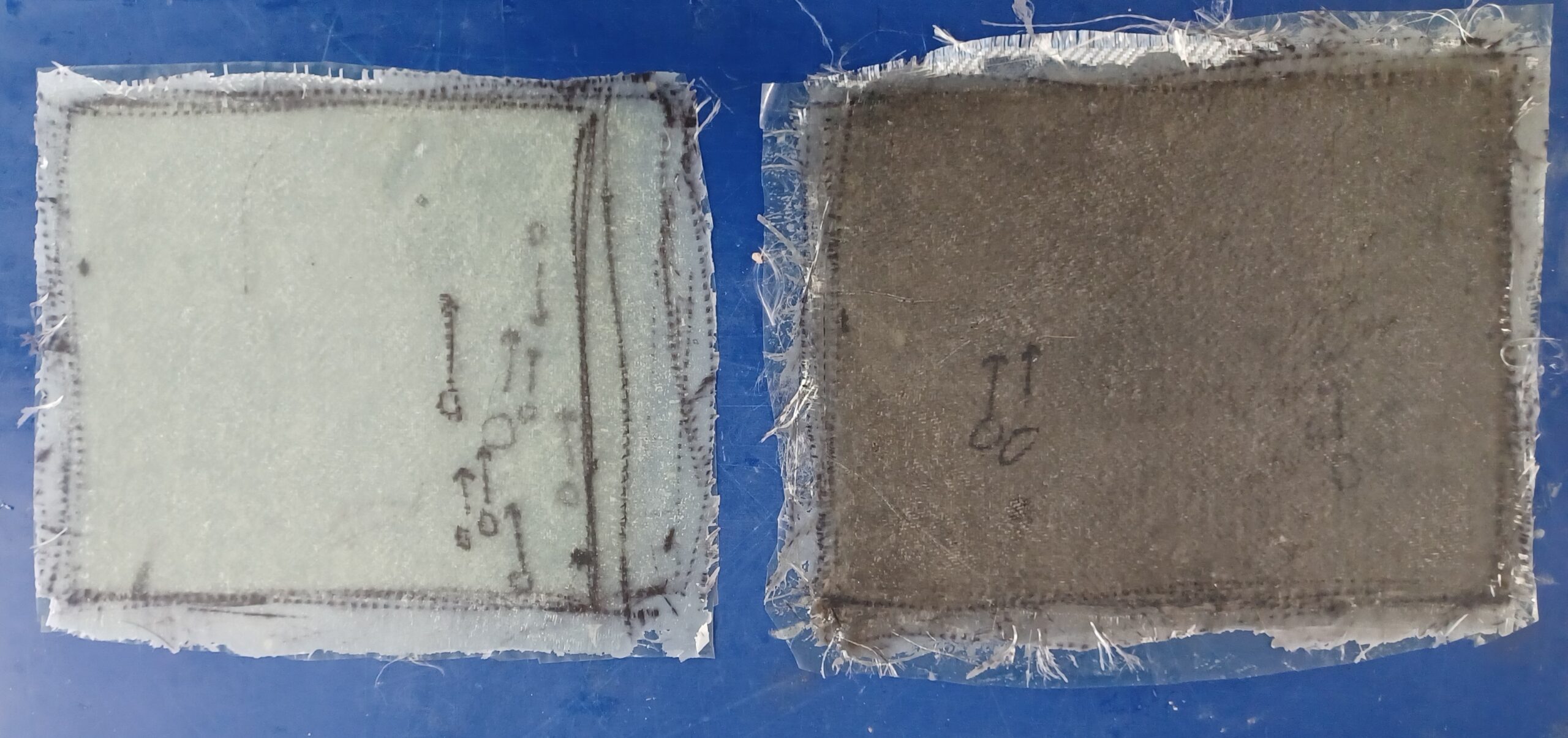

Welcome back everyone! Last week, I did the layup for the two main composite panels I will be testing. This is the first time I have used the graphene oxide we have.

For these composites, I used a slightly different, thicker fiberglass 2/2 twill weave. This allows my test samples to be slightly thicker so I can get more accurate readings during tensile testing. The graphene oxide we have is old, and a lot of the water evaporated out. To fix this, I refilled the bottle with 91% isopropyl alcohol to try and bring it back to its original concentration, 5mg/mL, but I can’t be exactly sure. Since isopropyl alcohol can mix with epoxy, unlike water, it gives us a bridge to transfer the graphene to the epoxy. After we mix the alcohol/GO solution with the epoxy, we can simply evaporate out the alcohol. After refilling the bottle, I mixed it and tried using a sonic cleaner to exfoliate the graphene as best as I could. This left us with a completely black liquid, which made it hard to see anything in the solution.

Based on the data we had, we decided to add 0.1% by weight of the GO solution to the epoxy, which amounts to about 9 mL per 2 ounces (there was a lot of conversion needed between imperial and metric units here). Once the epoxy was mixed, the rest of the wet layup process was the same. However, we vacuum bagged both composites this time, which pulls air out of the epoxy while it cures. Now, I need to add grips to both panels and start testing.