Fifth Week: Running into Problems

This week has been the exact opposite of last week. I ran into multiple obstacles, and have not progressed far.

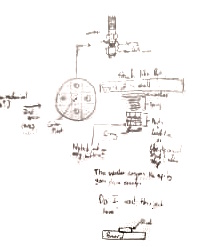

What I did accomplish is I figured out what to do for the control stick. I will recreate the mechanism that arcade sticks use, but with the ball enlarged into a disk. It should look somewhat like this:

I have micro switches, but I still need to find a material for the disc. I am considering lightweight and durable materials such as plexiglass or acrylic. I also want to add some sort of rubber/textured material to the disc to improve the user’s grip on the controller.

A significant challenge I encountered was shaping the wood for the box. I tried to file down the wood to make the cuts straight; however, the file left divots and bulges in the wood. I could not use the handsaw because it does not cut precisely enough. I accurately measured and cut new boards, but they also were not perfectly straight. I do not have access to a table saw, so I cannot make the cuts perfectly straight. At the worst, this will make the controller look sloppy, but it should function well.

The last issue I confronted was resizing the 3D model for the button. I’m not sure why this happened, but the measurements in Fusion360 were inaccurate compared to the actual 3D print. This was an issue with the original file that propagated into the enlarged model I made. Since I did not know if the model was accurately sized when I exported the file for printing, I could not make the hole on the bottom of the button the correct size for the electronic actuator. I tried to separate the polygons that make up the hole from the rest of the button but after I resized the button, the hole did not combine with the rest of the model.

Despite all of these problems, I am feeling optimistic about the controller. Once resolved, I can assemble the box for the controller and create the control stick. Overall, I am halfway done with the controller.