Week 5: Shank U, Next

Katie b -

This week, I was able to create a rough design of my new shank using SOLIDWORKS! It was a lengthy process that began with extracting the shank from a few old shoes. Since there’s no specific left or right shoe, I only needed to open up one from each pair. Initially, I had planned to remove just one shank, but given that I’ve worn different brands and varying shank strengths, I decided to take apart one of each.

The first shoe I tackled was by Russian Pointe (RP): a very classic and traditional brand. RP was home to many traditional Russian-made pointe shoe collections such as the En L’air and Jewel collections.

My first years en pointe (2019-2022) were always in these shoes, specifically the Brava model with a Flexible Hard (FH) shank. In the pictures below, you can see that the different layers in the sole area are held together by nails and a yellow glue, which does not smell very good by the way. Within this particular model, there are five main layers in the shoe’s bottom: the inner lining, inner sole, main shank, secondary shank, and outer sole (not pictured). However, after Russia’s invasion of Ukraine in 2022, these shoes were unable to be easily exported to places such as the United States due to sanctions. This caused RP to completely discontinue all of their Russian-made shoes by November of 2023, and introduce new models made in Thailand. For me, RP shoes have never been the same, and so I began searching for a new shoe.

The next three shoes I took apart are all by Virtisse: a women-owned and women-run company founded in 2021. In the world of pointe shoes, this brand is very new and small compared to industry powerhouses like Bloch, Freed, Grishko, Russian Pointe, etc.. For me, the coolest part is that the layers are sewn together rather than glued. This is one example of a small adjustment to the composition of a traditional pointe shoe. Virtisse shoes have quickly become my favorite, and they have become very popular amongst the dancers at my studio as about 90% of us wear them.

The first Virtisse shoe I was fitted in had a Medium (M) shank: a 3/4 length, reinforced (pink layer) shank. The shorter length makes it more flexible and easier to roll completely through. This is a good fit for new pointe dancers still building strength and stamina in their feet as well as experienced pointe dancers who are looking for a softer performance specific shoe.

The next Virtisse shoe I opened up has a Hard (H) shank: a full-length shank. This is typically the shoe I use for performances and graded examinations because it is flexible enough to create a nice bend along my arch but stiff enough to where I still feel supported.

My current class shoe, and the final shoe I pulled apart, is a Virtisse shoe with a Double Hard (HH) shank: a full-length, reinforced (pink layer) shank. This shank strength is good for strong pointe dancers in high-level classes, pre-professional programs, and professional companies.

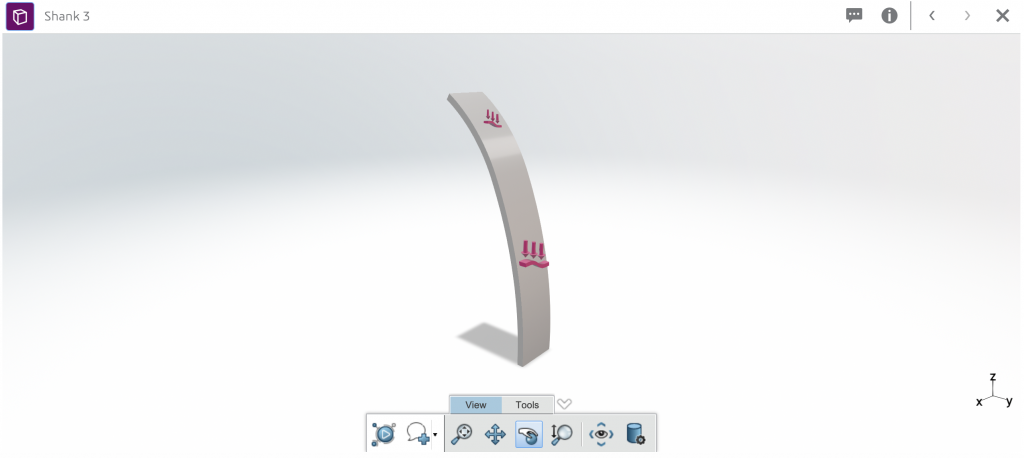

After opening up all four of these shoes, I made my rough design. I am still working on my SOLIDWORKS skills to be able to create a less rectangular shape, but this is what I have so far. I created a pre-arched shank that for now is made of Acrylonitrile Butadiene Styrene (ABS) and supports the load of a 130 lb dancer. The one similarity between Russian Pointe and Virtisse shoes that I found is the presence of a main shank, with a skinnier secondary shank positioned behind it, but I have yet to decide whether I will incorporate this into my design.

Next week will be very internship-focused for me, so I won’t have much time to experiment with my design, but I’ll dive back into it afterwards.

Comments:

All viewpoints are welcome but profane, threatening, disrespectful, or harassing comments will not be tolerated and are subject to moderation up to, and including, full deletion.